The Foundation of Realism – Mastering 3D Car Model Topology and Edge Flow

In the vibrant and ever-evolving landscape of 3D artistry, few subjects capture the imagination and demand as much technical prowess as the creation of realistic 3D car models. From the sleek lines of a modern supercar to the rugged charm of a classic off-roader, automotive models are a cornerstone for a multitude of industries. They serve as the backbone for breathtaking cinematic renders, immersive game environments, cutting-edge AR/VR experiences, precise engineering visualizations, and even tangible 3D prints.

The journey from concept to a fully realized, high-fidelity 3D car model is a complex interplay of artistic vision and technical mastery. It involves meticulous attention to detail in every aspect: the foundational topology that defines its form, the intricate UV maps that lay out its surfaces for texturing, the sophisticated PBR materials that dictate how light interacts with its paint and chrome, and the rigorous optimization required for real-time applications. This comprehensive guide will delve deep into the technical workflows and best practices essential for creating, optimizing, and utilizing premium 3D car models across various professional applications. Whether you’re a seasoned 3D artist, a game developer, an automotive designer, or a student aspiring to master the craft, prepare to unlock advanced insights into topology, texturing, rendering, and performance optimization that will elevate your automotive projects to an unparalleled level of realism and efficiency.

The Foundation of Realism – Mastering 3D Car Model Topology and Edge Flow

The secret to a visually stunning and functionally versatile 3D car model begins with its underlying mesh: the topology. Good topology isn’t just about looking clean; it’s about providing the structural integrity for smooth subdivision, efficient UV unwrapping, and flawless deformation. Automotive models, with their often intricate curves, sharp creases, and complex panel gaps, demand an exceptionally clean, quad-based topology to achieve production-ready quality. A poorly constructed mesh can lead to artifacts like pinching, undesirable shading, and difficulties in animation or real-time rendering, diminishing the perceived realism of the final asset.

For high-quality rendering and cinematic applications, 3D car models often require a significant polygon count to capture every minute detail. While a low-polygon base mesh is ideal for game development, a high-polygon mesh, ranging from 200,000 to over 1 million triangles, is common for hero assets in advertising or film. This allows for intricate details like drilled brake discs, detailed tire treads, and complex engine components to be modeled directly, rather than relying solely on normal maps. However, even high-poly models benefit from optimized, clean topology to ensure predictable subdivision and smooth reflections across their large, often reflective surfaces.

Understanding Edge Flow for Smooth Surfaces

Edge flow is paramount in automotive modeling. It refers to the direction and distribution of polygon edges, which dictates how light reflects off a surface and how the mesh deforms. For cars, critical areas like fender flares, door lines, hood creases, and window frames require carefully placed edge loops that follow the natural curvature and contours of the vehicle. These loops should be continuous and evenly spaced, especially in areas that will be subject to subdivision smoothing (like using a Turbosmooth modifier in 3ds Max or a Subdivision Surface modifier in Blender).

Incorrect edge flow can lead to unsightly pinching or lumps, particularly noticeable in specular highlights on reflective surfaces. Professionals ensure that edge loops effectively define both sharp creases and broad, sweeping curves. For instance, to create a crisp edge for a car door, you might use three or four tightly spaced edge loops, while a large, smooth panel like the hood would have widely spaced loops that gently follow its curvature. Mastering this balance is crucial for achieving physically accurate reflections and an overall polished aesthetic, which is a hallmark of high-quality 3D car models found on platforms like 88cars3d.com.

Optimizing Polygon Count Without Sacrificing Detail

The balance between visual detail and polygon efficiency is a constant challenge. For cinematic renders, raw polygon count is less of a concern than for interactive applications, but even then, unnecessary complexity can slow down viewport performance and render times. For game assets, polygon budgeting is critical. A typical game-ready car model might range from 50,000 to 150,000 triangles, depending on its importance and proximity to the camera.

Optimization techniques include using a multi-resolution approach, starting with a low-poly base and adding detail via subdivision, or baking normal maps from a very high-poly sculpt onto a more optimized mesh. Tools like ZBrush or Blender’s sculpting features are invaluable for creating high-detail meshes that can then be retopologized. When cleaning up meshes, aim to remove redundant edges, collapse small faces, and merge vertices that are too close. Decimation tools can reduce poly count, but should be used judiciously to avoid destroying crucial edge flow. For game assets, Level of Detail (LODs) are essential, providing different polygon counts for varying distances from the camera, dramatically improving real-time performance without compromising visual quality up close.

Bringing Surfaces to Life – UV Mapping and Texturing Strategies

Once the geometric form of your 3D car model is perfected, the next crucial step is to define how its surfaces will look. This involves UV mapping and the creation of physically based rendering (PBR) materials. UV mapping is the process of unfolding the 3D mesh into a 2D space, allowing 2D textures to be applied accurately. Without proper UVs, textures will appear stretched, distorted, or misaligned, ruining the realism of even the best-modeled car. PBR materials, on the other hand, ensure that your car interacts with light in a physically accurate manner, resulting in incredibly lifelike surfaces, from the gleam of polished chrome to the subtle wear of a leather interior.

The quality of your textures is directly tied to the effectiveness of your UV layout. A well-organized UV map provides consistent texel density across all surfaces, prevents seams from being overly noticeable, and maximizes the use of texture space. For car models, which often feature large, smooth panels alongside intricate details, a strategic approach to UV unwrapping is non-negotiable. Furthermore, leveraging the power of PBR material workflows is essential for achieving the photorealistic results expected in modern 3D visualization and game development.

Efficient UV Unwrapping for Automotive Surfaces

Effective UV unwrapping for a car model involves several key strategies. Firstly, break down the car into logical, material-specific sections (e.g., body panels, glass, tires, interior components). Each section can have its own UV island, minimizing distortion and simplifying the texturing process. Aim for minimal stretching by using projection methods like planar, cylindrical, or spherical, then refining with tools like Blender’s Smart UV Project, 3ds Max’s Peel, or Maya’s Unfold. The goal is to create UV islands that are as rectangular as possible, making them easier to paint and ensuring consistent texel density.

Texel density—the number of texture pixels per unit of surface area—should be as uniform as possible across all visible parts of the car. This prevents some areas from looking pixelated while others appear blurry. Overlapping UVs can save texture space for symmetrical parts (like side mirrors or wheels) but should be used cautiously for unique details. For larger panels, strategically placing seams along natural creases or hard edges (where they will be less noticeable) is critical. Techniques like UDIMs (multi-tile UVs) are also valuable for extremely high-detail models, allowing different parts of the car to utilize separate texture sets for incredible resolution.

Crafting Realistic PBR Materials and Shader Networks

PBR (Physically Based Rendering) materials are the industry standard for achieving photorealism. They are designed to simulate how light behaves in the real world, based on physical properties of materials like metallicness and roughness. For a car, this means creating distinct PBR material sets for every surface: the reflective, metallic car paint (often with a clear coat layer), the highly refractive glass, the matte rubber of tires, the brushed aluminum of trim, and the various textures of the interior.

A typical PBR shader network for a car material includes several maps:

- Albedo/Base Color: The inherent color of the surface, free from lighting information.

- Metallic: A grayscale map defining whether a surface is metallic (white) or dielectric (black).

- Roughness: Controls the microscopic surface irregularities, influencing how blurry or sharp reflections are.

- Normal Map: Adds fine surface detail (like tiny scratches or panel lines) without increasing polygon count.

- Ambient Occlusion (AO): Simulates soft shadows where surfaces are close together.

- Opacity/Alpha: For transparent or cutout elements like glass or grilles.

- Clear Coat: Essential for car paint, simulating a reflective top layer over the base metallic paint.

Software like Substance Painter is a powerful tool for creating and painting these PBR textures, allowing artists to layer realistic dirt, grime, and wear effects. Understanding the interplay of these maps and how to author them accurately is paramount for making your 3D car models truly come alive.

Visualizing Perfection – Advanced Automotive Rendering Techniques

Once your 3D car model is meticulously crafted and textured with PBR materials, the final step in bringing it to life for static images or animations is rendering. This is where the magic happens, transforming your digital asset into a stunning, photorealistic image. Achieving a professional-grade automotive render involves mastering lighting, environment setup, renderer-specific settings, and post-processing. The goal is not just to illuminate the car, but to tell a story, highlight its design, and evoke emotion, making the viewer believe they are looking at a real vehicle.

Different rendering engines, such as Corona Renderer, V-Ray, Cycles, and Arnold, each offer unique strengths and workflows, but the fundamental principles of good lighting and material interaction remain consistent. A truly captivating automotive render emphasizes the car’s form, the quality of its surfaces, and its presence within a believable scene. This requires a deep understanding of how light behaves in the real world and how to replicate that digitally, complemented by careful attention to composition and post-production polish.

Mastering Lighting and Environment Setup

Lighting is the single most critical factor in a realistic render. For automotive models, High Dynamic Range Images (HDRIs) are often the starting point. An HDRI can provide realistic ambient lighting, accurate reflections, and an environmental background, effectively placing the car in a real-world setting. Complementing HDRIs with artificial studio lighting, such as area lights or photometric lights, allows for precise control over highlights, shadows, and overall mood.

Common studio setups include:

- Three-Point Lighting: Key light, fill light, and back light to define form and separate the car from the background.

- Softbox/Strip Lights: Used to create long, elegant reflections along the car’s body panels, emphasizing its curves.

- Rim Lights: Positioned behind and to the sides of the car to create a bright outline, adding depth and drama.

- Reflection Probes: In real-time engines, these capture environmental reflections and apply them to reflective surfaces, crucial for car paint and chrome.

Understanding the interplay of direct and indirect lighting, and how different light sources affect material properties (especially reflections), is key to achieving a visually striking render. Experimenting with different HDRI environments, from sun-drenched exteriors to moody industrial interiors, can dramatically alter the perception of your model.

Rendering with Industry-Standard Engines (Corona, V-Ray, Cycles, Arnold)

Each renderer offers a powerful suite of tools to achieve photorealism:

- Corona Renderer (3ds Max, Cinema 4D): Known for its ease of use, physically accurate light transport, and rapid interactive rendering. Ideal for architectural visualization and automotive studios that prioritize quick iterations and high-quality results. Specific settings to focus on include noise level limits, global illumination (GI) solvers, and depth of field.

- V-Ray (3ds Max, Maya, SketchUp, Rhino): A industry workhorse, offering immense control over every aspect of rendering. It excels in complex scene management and robust production pipelines. Key areas to adjust include image samplers, GI engines (e.g., Brute Force + Light Cache), and render elements for compositing.

- Cycles (Blender): Blender’s integrated path-tracing engine provides highly realistic results with excellent integration into the Blender workflow. Leveraging GPU rendering (CUDA/OptiX) and understanding light paths, caustics, and denoising settings are essential for efficient high-quality renders.

- Arnold (Maya, 3ds Max, Houdini): A favorite in film and animation for its robust handling of complex scenes, impressive ray-tracing capabilities, and photorealistic output. Focus on adaptive sampling, volume rendering for atmospherics, and deep EXR output for compositing.

Regardless of the engine, always prioritize physically accurate material setups, high-resolution textures (4K or 8K for hero assets), and a well-balanced lighting scheme. Experiment with render passes (diffuse, specular, reflections, shadows, Z-depth) to gain maximum flexibility in post-processing.

Post-Processing and Compositing for Impact

A raw render straight from the engine rarely looks finished. Post-processing and compositing in software like Adobe Photoshop, Affinity Photo, or Nuke are crucial steps to elevate your automotive renders from good to exceptional. This stage allows you to make subtle yet impactful adjustments without re-rendering the entire scene.

Key post-processing techniques include:

- Color Grading: Adjusting hue, saturation, and luminance to enhance mood and visual appeal.

- Exposure and Contrast Adjustment: Fine-tuning brightness and dynamic range.

- Vignetting: Subtly darkening the edges of the image to draw attention to the car.

- Chromatic Aberration: A subtle lens distortion effect that adds realism.

- Sharpening: Enhancing details, especially for textures and edges.

- Adding Effects: Lens flares, glow effects for headlights/taillights, dust particles, and atmospheric haze can significantly enhance realism and drama.

- Compositing Render Elements: Combining separate passes (e.g., reflections, shadows, ambient occlusion) for precise control over each aspect of the image.

This final polish helps to integrate the 3D car model seamlessly into its background, correct minor imperfections, and create a visually cohesive and striking image. Platforms like 88cars3d.com rely on these techniques to showcase their high-quality 3D car models in the best possible light.

Performance and Portability – Optimizing 3D Car Models for Interactive Applications

While cinematic renders prioritize absolute visual fidelity, interactive applications like video games, AR/VR experiences, and real-time configurators demand a careful balance between aesthetics and performance. A beautifully rendered 3D car model can become a heavy, unmanageable asset in a game engine if not properly optimized. The challenge lies in maintaining visual quality while adhering to strict polygon budgets, draw call limitations, and texture memory constraints. This section focuses on the technical strategies required to prepare 3D car models for the demanding environments of real-time rendering, ensuring smooth frame rates and broad compatibility across various platforms.

The rise of interactive media has made optimization a critical skill for any 3D artist. Understanding how game engines and AR/VR platforms process assets, and knowing which file formats offer the best performance and portability, is crucial. High-quality game assets, particularly detailed vehicles, are often the centerpiece of interactive experiences, requiring meticulous attention to optimization from the ground up.

Game Engine Optimization (Unity, Unreal Engine)

Optimizing 3D car models for game engines like Unity and Unreal Engine involves a multi-faceted approach to reduce computational load without sacrificing visual quality.

- Level of Detail (LODs): Create multiple versions of the car model, each with progressively lower polygon counts. The engine switches between these LODs based on the camera’s distance, ensuring high detail up close and efficient rendering far away. A typical car might have 3-5 LODs (e.g., LOD0: 100k tris, LOD1: 50k tris, LOD2: 20k tris, LOD3: 5k tris).

- Draw Call Reduction: Combine multiple meshes into a single mesh where possible (e.g., car body, chassis, interior, and wheels might be separate meshes for easier animation/damage, but smaller details like bolts could be merged). Use texture atlases to consolidate materials and reduce the number of texture swaps the GPU needs to perform.

- Texture Atlasing: Consolidate multiple smaller textures (e.g., for different interior parts) into one large texture map. This reduces draw calls and improves cache performance.

- Efficient UVs: Ensure UVs are optimized for space and avoid overlapping unless specifically for symmetrical elements that use the same texture space.

- Collision Meshes: Use simplified collision meshes (often convex hulls or simple box colliders) instead of the high-poly visual mesh to reduce physics calculations.

- Occlusion Culling: Implement occlusion culling to prevent rendering objects that are hidden behind other objects (e.g., engine parts when the hood is closed).

- Static vs. Dynamic Objects: Mark static car elements as static in the engine to allow for pre-computed lighting and occlusion, improving runtime performance.

Adhering to target frame rates (e.g., 60 FPS for PC, 30 FPS for mobile) guides these optimization efforts, ensuring a smooth and enjoyable user experience.

Preparing Models for AR/VR Experiences

AR/VR applications impose even stricter performance requirements due to the need for high frame rates (typically 90 FPS or higher) and lower latency to prevent motion sickness.

- Aggressive Poly Count Reduction: Models for mobile AR/VR might need to be significantly lower poly, perhaps under 30,000-50,000 triangles for a hero vehicle, especially for stand-alone headsets. High-detail information is baked into normal maps from a high-poly source.

- Optimized Materials: Use lightweight PBR shaders. Avoid complex shader graphs or excessive transparency/refraction that can be costly in real-time. Metallic-Roughness workflow is generally preferred over Specular-Glossiness for AR/VR.

- Batching: Maximize batching by using as few materials and textures as possible.

- Platform-Specific Formats: Leverage formats like GLB (for web AR/VR and Android) and USDZ (for Apple ARKit) which are highly optimized for real-time viewing and smaller file sizes.

When sourcing 3D car models from marketplaces such as 88cars3d.com, look for assets specifically labeled as “game-ready” or “AR/VR optimized,” as they will already incorporate many of these best practices.

Navigating File Formats and Conversions (FBX, OBJ, GLB, USDZ)

The world of 3D file formats can be complex, each serving different purposes and offering varying levels of compatibility and feature support.

- FBX (Filmbox): Autodesk’s proprietary format is the industry standard for interoperability between 3D applications (Maya, 3ds Max, Blender) and game engines (Unity, Unreal). It supports geometry, materials, textures, animations, rigging, and cameras. It’s robust but can sometimes be verbose.

- OBJ (Wavefront Object): A universal format, highly compatible but simpler than FBX. It primarily stores geometry (vertices, faces, UVs) and references external MTL (material) files for basic material properties. It does not support animation or rigging. Excellent for static meshes.

- GLB (Binary glTF): The binary version of glTF (GL Transmission Format) is becoming the standard for 3D models on the web, AR/VR, and real-time applications. It’s efficient, small, and supports PBR materials, animations, and skeletal rigging. Ideal for lightweight, interactive 3D.

- USDZ (Universal Scene Description Zip): Apple’s proprietary format for AR experiences on iOS devices. It’s a packed, optimized format based on Pixar’s USD, designed for real-time AR with PBR materials and animations. Essential for targeting Apple’s ecosystem.

When converting between formats, always check for data integrity. Ensure materials, UVs, and vertex normals are correctly transferred. Use the appropriate export settings within your 3D software to optimize for the target platform (e.g., triangulate mesh for game engines, embed media for GLB). The availability of multiple formats for a single model, as often offered by 88cars3d.com, greatly enhances its utility and versatility.

Beyond Visualization – 3D Car Models in Specialized Applications

The utility of high-quality 3D car models extends far beyond traditional rendering and interactive experiences. They are invaluable tools in highly specialized fields such as 3D printing and professional automotive design and visualization. Each of these applications comes with its own set of technical demands and best practices, requiring the 3D artist to prepare models in specific ways to ensure functionality, accuracy, and optimal results. Understanding these nuances allows for a broader application of 3D modeling skills and expands the potential value of digital automotive assets.

Whether creating a physical prototype, a scale model, or integrating 3D data into advanced design workflows, the underlying quality and preparation of the 3D car model are paramount. These specialized applications often bridge the gap between the digital and physical worlds, or between different stages of a product’s lifecycle, demanding a comprehensive understanding of the entire 3D pipeline.

Prepping 3D Car Models for 3D Printing

Transforming a digital 3D car model into a physical object via 3D printing requires strict adherence to specific mesh integrity rules. Unlike rendering, where minor mesh imperfections might go unnoticed, 3D printers require a “watertight” or “manifold” mesh – meaning every edge must be shared by exactly two faces, and there should be no holes, inverted normals, or self-intersecting geometry. Any deviation can lead to printing errors, failed prints, or models with structural weaknesses.

Key considerations for 3D printing:

- Watertight Mesh: Ensure the model has a completely enclosed volume, with no gaps or holes. Tools like Blender’s 3D Print Toolbox, Meshmixer, or Netfabb are excellent for analyzing and repairing meshes.

- Wall Thickness: Ensure all parts of the model meet the minimum wall thickness requirements of the chosen 3D printer and material. Thin elements like antenna or small mirrors might need to be thickened or simplified.

- Scale: Models must be scaled correctly to the desired physical dimensions. Units should be consistent (e.g., millimeters for FDM, meters for design visualization).

- Mesh Resolution: While high detail is good, excessive polygons can lead to large file sizes and complex slicing. Decimate meshes where appropriate, ensuring crucial details are preserved.

- Support Structures: Consider overhangs and unsupported areas that will require support material during printing. Sometimes, designing a model in separate, easily printable parts is more efficient.

- Tolerance: For multi-part models that need to fit together, ensure sufficient tolerance (e.g., 0.1-0.3mm gap) between mating surfaces to account for printer inaccuracies.

Preparing a detailed car model for 3D printing can be a meticulous process, but it allows for rapid prototyping, creation of physical collectibles, or even custom parts.

Automotive Design and Visualization Workflows

In the automotive industry, 3D car models are central to the entire design and marketing process. From initial concept sketches to final production, 3D models provide the tools for iteration, validation, and presentation.

- Concept Validation: Designers use 3D models to quickly iterate on different styling cues, body shapes, and aesthetic details, visualizing changes in real-time. This can involve importing CAD data (e.g., from SolidWorks, CATIA, Alias) into 3D DCC tools for rendering and presentation.

- Marketing and Advertising: High-fidelity 3D car models are essential for creating stunning advertisements, promotional videos, and configurators that allow potential customers to customize vehicles in real-time. These models must be impeccably detailed and optimized for both high-end rendering and interactive web experiences.

- Virtual Showrooms and Configurators: Interactive 3D configurators, often built in game engines like Unreal Engine, allow users to change colors, wheels, interiors, and even view the car in different environments, providing an immersive shopping experience.

- AR for Sales and Service: Augmented Reality applications allow customers to virtually place a full-scale car in their driveway or explore its features using their smartphone, enhancing engagement and providing a realistic preview.

- Simulations and Engineering: While often using different software, visualization models can sometimes be adapted for aerodynamics simulations or crash testing scenarios, though these typically require highly specific engineering meshes.

The ability to quickly adapt and integrate 3D car models into these diverse professional workflows is a critical skill. Resources like 88cars3d.com provide a valuable starting point for designers and studios seeking high-quality, pre-optimized assets that can be customized and integrated into their pipelines with minimal friction.

Conclusion

The journey through the intricate world of 3D car models reveals a fascinating blend of artistic skill and rigorous technical understanding. From meticulously crafting clean topology and edge flow that defines every curve, to precisely unwrapping UVs for flawless PBR material application, and finally, optimizing for diverse platforms, each step is crucial for achieving truly professional results. We’ve explored the nuances of advanced automotive rendering, leveraging powerful engines like Corona and Cycles, and delved into the critical optimization strategies required for seamless integration into game engines and cutting-edge AR/VR experiences. Furthermore, we’ve touched upon the specialized requirements for 3D printing and the pivotal role 3D models play in modern automotive design workflows.

The pursuit of photorealism and functional efficiency in 3D car modeling is an ongoing learning process, demanding constant adaptation to new technologies and evolving industry standards. By mastering the core principles of topology, UV mapping, PBR material creation, rendering, and optimization, you equip yourself with the tools to tackle virtually any automotive visualization challenge. Remember that high-quality assets form the bedrock of any successful project. For those seeking to accelerate their creative process and ensure top-tier results, exploring curated marketplaces offering production-ready 3D car models, like those available on 88cars3d.com, can provide an invaluable head start. Keep practicing, keep experimenting, and continue pushing the boundaries of what’s possible with 3D automotive artistry.

Featured 3D Car Models

Nissan Micra 2010 3D Model

Texture: Yes

Material: Yes

Download the Nissan Micra 2010 3D Model featuring clean geometry, realistic detailing, and a fully modeled interior. Includes .blend, .fbx, .obj, .glb, .stl, .ply, .unreal, and .max formats for rendering, simulation, and game development.

Price: $4.99

Mercedes-Benz SLR McLaren 3D Model

Texture: Yes

Material: Yes

Download the Mercedes-Benz SLR McLaren 3D Model featuring clean geometry, realistic detailing, and a fully modeled interior. Includes .blend, .fbx, .obj, .glb, .stl, .ply, .unreal, and .max formats for rendering, simulation, and game development.

Price: $4.99

Mitsubishi Eclipse GT 2001 3D Model

Texture: Yes

Material: Yes

Download the Mitsubishi Eclipse GT 2001 3D Model featuring clean geometry, realistic detailing, and a fully modeled interior. Includes .blend, .fbx, .obj, .glb, .stl, .ply, .unreal, and .max formats for rendering, simulation, and game development.

Price: $4.99

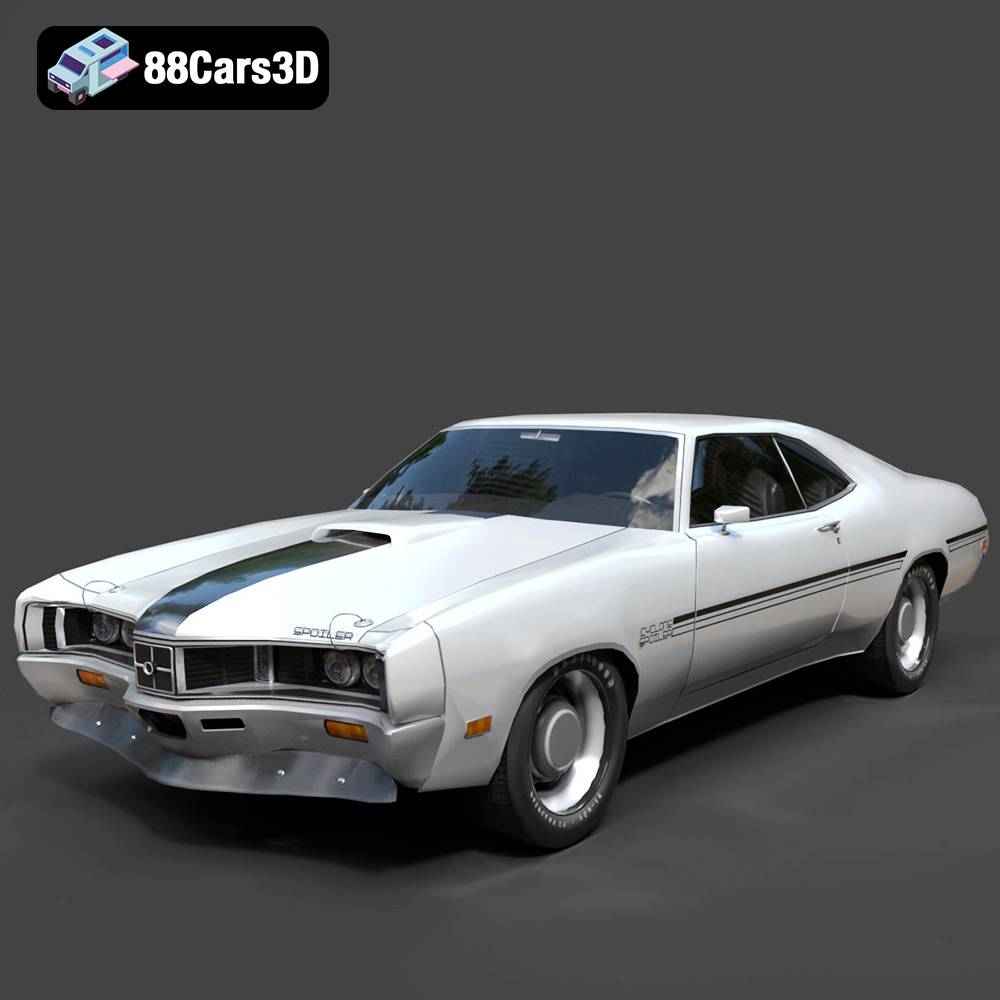

Mercury Cyclone Spoiler 1970 3D Model

Texture: Yes

Material: Yes

Download the Mercury Cyclone Spoiler 1970 3D Model featuring clean geometry, realistic detailing, and a fully modeled interior. Includes .blend, .fbx, .obj, .glb, .stl, .ply, .unreal, and .max formats for rendering, simulation, and game development.

Price: $4.99

Opel Astra 3D Model

Texture: Yes

Material: Yes

Download the Opel Astra 3D Model featuring clean geometry, realistic detailing, and a fully modeled interior. Includes .blend, .fbx, .obj, .glb, .stl, .ply, .unreal, and .max formats for rendering, simulation, and game development.

Price: $4.99

Mitsubishi Lancer Evolution VIII 2003 3D Model

Texture: Yes

Material: Yes

Download the Mitsubishi Lancer Evolution VIII 3D Model featuring clean geometry, realistic detailing, and a fully modeled interior. Includes .blend, .fbx, .obj, .glb, .stl, .ply, .unreal, and .max formats for rendering, simulation, and game development.

Price: $4.99

Peugeot 307 3D Model

Texture: Yes

Material: Yes

Download the Peugeot 307 3D Model featuring clean geometry, realistic detailing, and a fully modeled interior. Includes .blend, .fbx, .obj, .glb, .stl, .ply, .unreal, and .max formats for rendering, simulation, and game development.

Price: $4.99

Peugeot 207 3D Model

Texture: Yes

Material: Yes

Download the Peugeot 207 3D Model featuring clean geometry, realistic detailing, and a fully modeled interior. Includes .blend, .fbx, .obj, .glb, .stl, .ply, .unreal, and .max formats for rendering, simulation, and game development.

Price: $4.99

Mitsubishi Lancer Evolution VI 3D Model

Texture: Yes

Material: Yes

Download the Mitsubishi Lancer Evolution VI 3D Model featuring clean geometry, realistic detailing, and a fully modeled interior. Includes .blend, .fbx, .obj, .glb, .stl, .ply, .unreal, and .max formats for rendering, simulation, and game development.

Price: $4.99

Nissan Moco 007 3D Model

Texture: Yes

Material: Yes

Download the Nissan Moco 007 3D Model featuring clean geometry, realistic detailing, and a fully modeled interior. Includes .blend, .fbx, .obj, .glb, .stl, .ply, .unreal, and .max formats for rendering, simulation, and game development.

Price: $4.99